半岛(中国)

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

半岛(中国)

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

PRODUCTS

PRODUCTS

Shengli Centrifuge Manufacturing

VZU automatic desulfurization gypsum dewatering centrifuge

I. Overview:

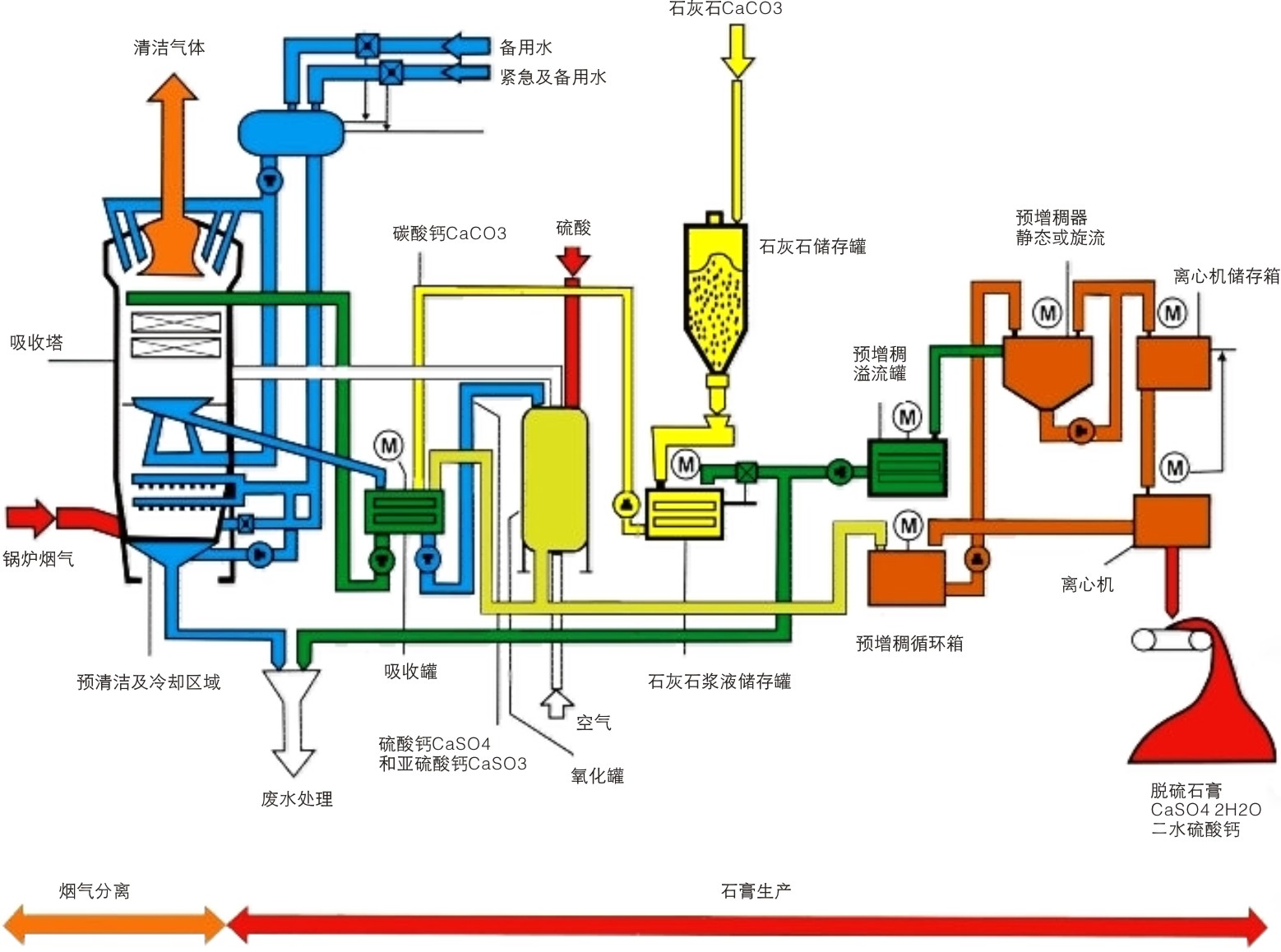

FGD wet flue gas desulfurization technology is usually used in thermal power plants, waste incineration plants, cement plants and other products to produce sulfur dioxide in the automatic desulfurization process.

The gypsum produced by the FGD process can be separated from the mother liquor and cleaned by the VZU type desulfurized gypsum vertical scraper discharge automatic centrifuge. The finished product can be used to make gypsum board for construction, special gypsum board (sound insulation board, etc. ) Or as additives and filling materials.

Relying on many years of centrifuge research and development and application experience, and on the basis of absorbing and drawing on the advanced technology of similar foreign products, the company has developed and produced the VZU type desulfurized gypsum dewatering——full-automatic vertical scraper lower discharge centrifuge with technical parameters It has the advantages of high reliability, good dewatering effect, fully automatic operation, high output, etc., stable operation and excellent performance under long-term production and various complex and harsh conditions, ensuring the maximum dewatering capacity of gypsum slurry and meeting production need.

This equipment can also be used in the occasions that require large solid output, better suspension filtration performance, and large solid particle size.

2. Obvious cost advantage:

◆Low energy consumption and low energy cost. Only in the short period of feeding and accelerating, the full power of the motor needs to be exerted, and the other time is running at low power.

◆The amount of flushing fluid is small, which reduces the cost of water.

◆Small floor space (approximately 2/3 less than the vacuum filter belt), and the construction cost is significantly reduced.

◆Fully enclosed full-automatic centrifuge system, which is cleaner to operate and reduces the cost of related equipment.

◆Reduced maintenance and maintenance costs (for example, no need to maintain vacuum pumps, etc.)

3. Environmental protection:

◆Fully enclosed centrifuge system makes the working environment cleaner with low noise (<85 dB).

◆The finished desulfurized gypsum can be used in construction and other industries instead of being stacked in landfills to cause secondary environmental pollution.

◆Energy, water, maintenance costs and environmental protection concepts have received increasing attention. Shengli gypsum dewatering centrifuges have advantages in these aspects.

4. High-quality products:

◆High flushing efficiency, low chlorine content of gypsum (less than 100ppm), high product purity.

◆High solid-liquid separation efficiency, low residual moisture content of gypsum (6-10% w/w).

5. Cost comparison between centrifuge and vacuum filter belt:

Compared with the vacuum filter belt, the purchase cost of the centrifuge system is slightly higher, but the centrifuge failure rate is low, the process is fully automatic, and unnecessary losses are avoided. Operating costs (maintenance, energy consumption, etc.) are low. Long service life. After 4-5 years of operation, the total cost of the centrifuge system is much lower than that of the vacuum filter belt.

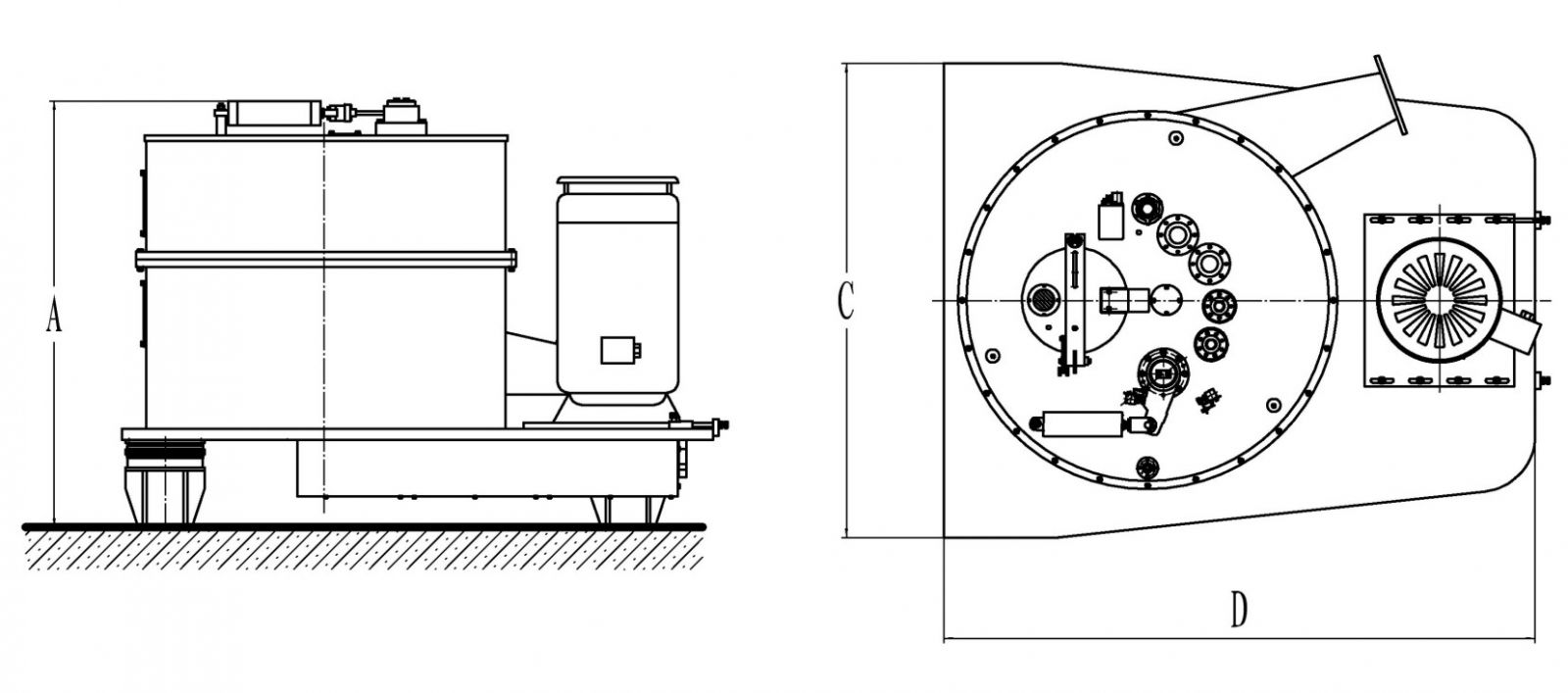

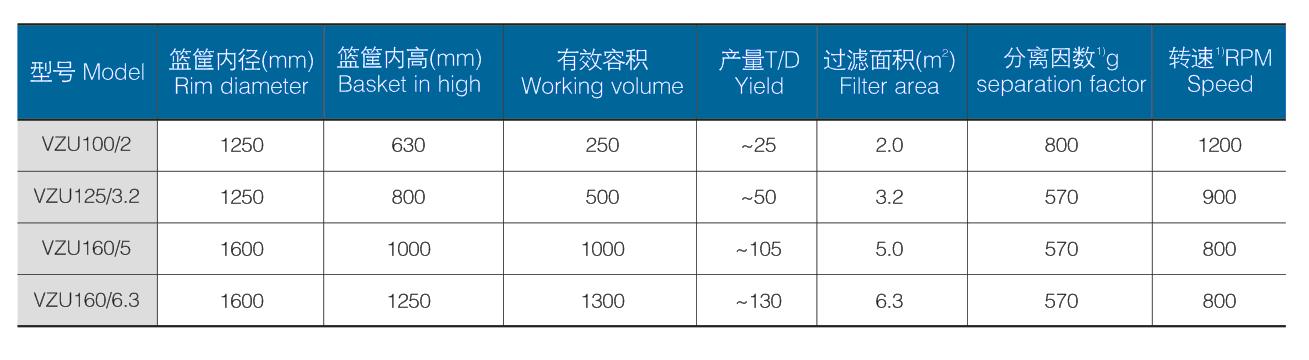

6, technical parameters, dimensions and weight

1) The calculation basis for the above data is 50 degrees Celsius, and the bulk density of the filter cake at saturated humidity is 1750kg/m3.

FGD wet flue gas desulfurization technology

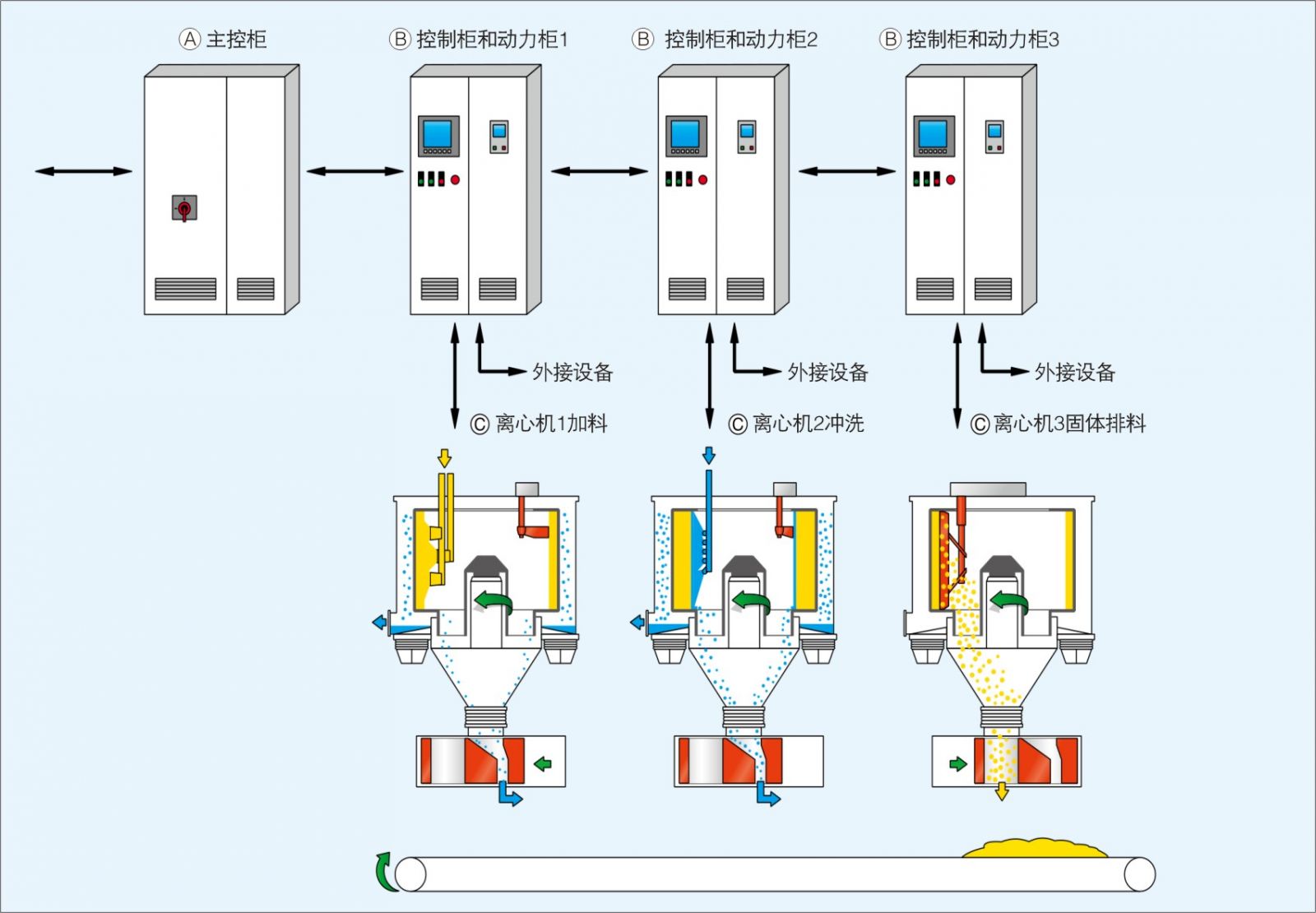

Fully automated solution in the application of desulfurization gypsum dehydration centrifuge

HOME | ABOUT US | PRODUCTS | NEWS | SERVICE | FACTORY | HONORS | ORDER | CONTACT | 中文版

Copyright(C)2021, Jiangsu Shengli Centrifuge Manufacturing Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备16066832号